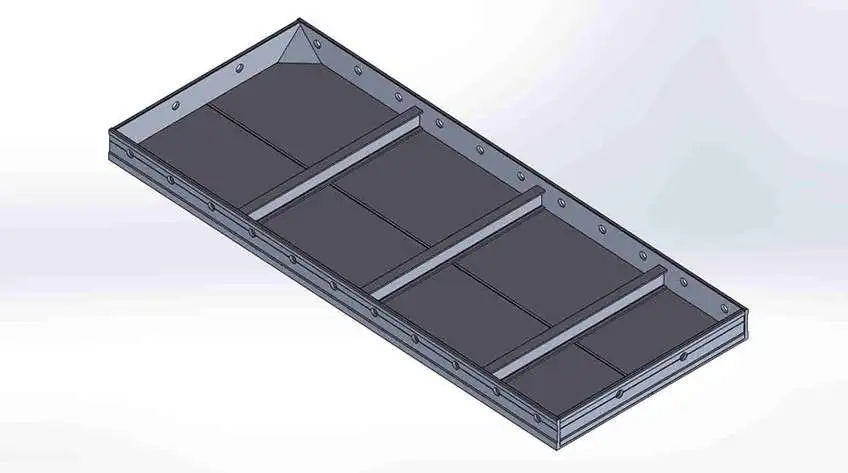

Aluminium Formwork Panels

Modern construction projects demand speed, precision, and cost efficiency. Aluminium formwork panels offer all three, making them the preferred choice for high-rise buildings, residential complexes, and commercial structures.

These panels are lightweight, durable, and reusable, forming a critical part of the aluminium formwork system that streamlines construction while ensuring high-quality results.

What Are Aluminium Formwork Panels?

Aluminium formwork panels are high-strength moulds made from aluminium alloys that shape concrete for walls, slabs, columns, and beams.

Key Features:

- Lightweight and easy to transport

- Strong and durable for repeated use

- Smooth surface finish reduces plastering costs

- Corrosion-resistant for long-term use

Technical Specifications

- Alloy Type: Aluminium 6061 / AA

- Panel Thickness: 1.5–3 mm (depending on design)

- Load Capacity: Supports standard concrete load safely

- Panel Size Options: Customizable for slab, wall, and column applications

- Fire & Weather Resistance: Suitable for Indian climatic conditions

Advantages of Aluminium Formwork Panels

| Advantage | Benefit |

|---|---|

| Lightweight | Easier handling and faster installation |

| High Strength | Supports heavy concrete safely |

| Reusable | Cost-effective up to 200 cycles |

| Precision Finish | Smooth walls and slabs with minimal finishing |

| Faster Construction | Shorter slab cycles, quicker project completion |

| Eco-Friendly | Reduces timber use and construction waste |

| Worker Safety | Designed for stable on-site installation |

How Aluminium Formwork Panels Work

- Panels are assembled on-site according to project design.

- Concrete is poured into the mould.

- After setting, panels are dismantled carefully.

- Panels are cleaned and reused for the next slab or wall.

Installation & Handling Guidelines

- Use trained staff for panel assembly and alignment.

- Ensure proper cleaning and storage after each use to maintain panel life.

- Use appropriate accessories like wedges and pins for secure installation.

- Follow safety protocols to prevent accidents on-site.

Common Problems and Solutions

| Problem | Solution by Nilkanth |

|---|---|

| Misalignment of panels | On-site technical supervision and layout adjustment |

| Surface imperfections | Use high-precision panels and proper assembly |

| Missing accessories | Predictive accessory supply and replacements |

| Wear & tear | Expert guidance on handling and maintenance |

Cost and ROI Benefits

- Reduced Labour Costs: Lightweight panels reduce manpower needs.

- Faster Slab Cycles: Shorter construction timelines.

- Reusability: Panels last 200+ cycles, lowering per-project cost.

- Less Material Waste: Reduced timber and plaster usage.

Nilkanth Aluminium Formwork: Built for India

- Manufactured in Gujarat, with rapid support for Maharashtra, Delhi NCR, and other regions.

- Provides technical guidance, on-site supervision, and maintenance tips.

- Partner-first approach ensures reliability, speed, and cost-efficiency.