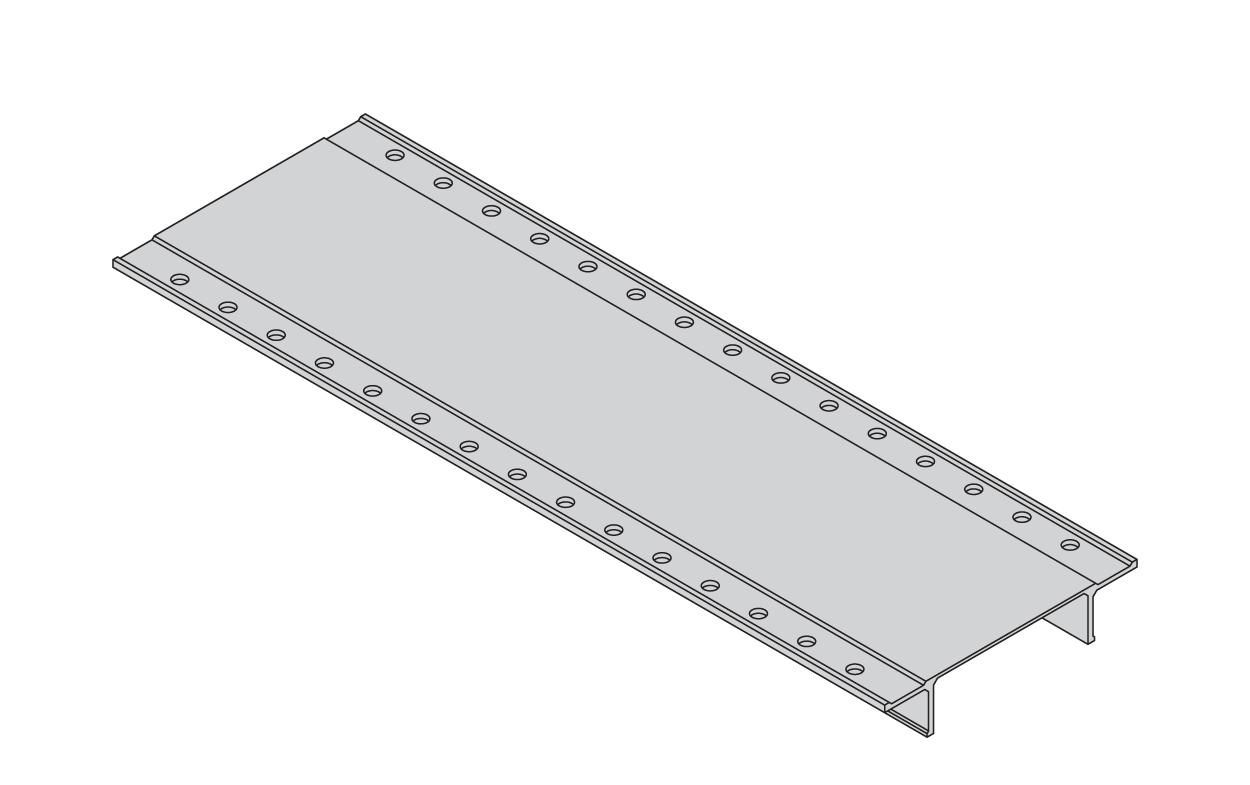

The Beam Bottom Panel in Aluminum Formwork

The Beam Bottom Panel is a significant component in an aluminum formwork system specifically designed for constructing the bottom part of a beam. It serves as the formwork panel that supports the concrete and carries the majority of the bulk load during the construction process

The Beam Bottom Panel is typically a rectangular or trapezoidal-shaped panel made from high-quality aluminum alloy. It is engineered to withstand heavy loads and provide structural stability. The panel's size and dimensions are customized to match the specific requirements of the beam being formed.

The primary function of the Beam Bottom Panel is to create a strong and stable surface to support the weight of the concrete being poured. It ensures that the concrete remains in place and takes the shape of the desired beam structure. The panel distributes the load evenly across its surface, reducing stress concentration and preventing deformations or failures.

The Beam Bottom Panel is securely connected to other formwork components, such as vertical panels, beams, or props, to create a complete formwork system. This integration ensures the stability and alignment of the formwork during the pouring and curing of concrete.

Advantages

- Load-bearing Capacity: The rocker allows precise adjustments, aligning the system accurately for consistent concrete elements.

- Formwork Alignment:By absorbing misalignments, it distributes loads evenly, minimizing damage risk and defects.

- Ease of Installation: Rockers integrate seamlessly, simplifying assembly and disassembly.

- Reusability: The durable construction of the panel allows for multiple uses over different construction projects. Its resistance to wear and tear promotes sustainability and cost-effectiveness.

In summary, the Beam Bottom Panel in an aluminum formwork system is a critical component that supports the weight of the concrete during beam construction. Its load-bearing capacity, precise alignment, and ease of installation contribute to efficient and high-quality construction processes.