Optimize Construction with the Beam Side Panel

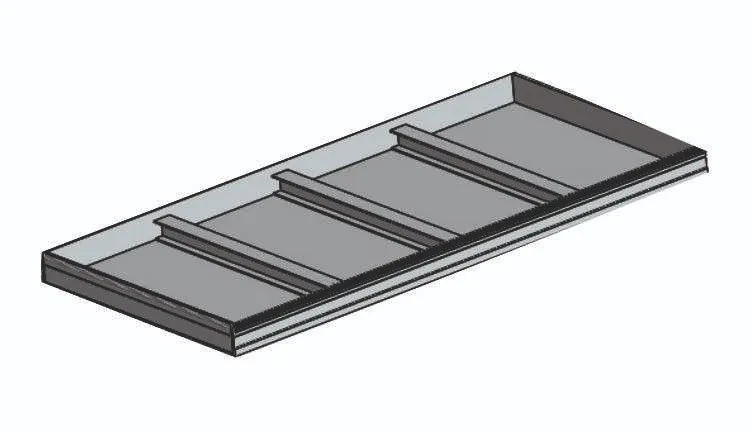

The Beam Side Panel is a key component in an aluminum formwork system specifically designed to support the sides of beams during construction. It is utilized to create a stable formwork structure that matches the depth of the beam being formed.

The Beam Side Panel is typically a rectangular panel made from high-grade aluminum alloy. It is precisely manufactured to align with the dimensions and depth of the beam. The panel is designed to securely hold the sides of the beam in place and provide a smooth surface for the concrete to be poured against.

The primary function of the Beam Side Panel is to support the sides of the beam and maintain their shape during the pouring and curing of concrete. It prevents any lateral movement or distortion of the beam, ensuring accurate and consistent dimensions.

The Beam Side Panel is installed vertically and securely connected to the formwork system, typically using interlocking mechanisms such as hooks or clamps. The panel is aligned with the sides of the beam and adjusted to match the required depth.

Advantages

- Stability and Support:By absorbing misalignments, it distributes loads evenly, minimizing damage risk and defects.

- Easy Installation and Removal: The lightweight nature of the Beam Side Panel allows for easy handling, assembly, and disassembly. This facilitates efficient installation and removal processes, saving time and labor costs.

- Reusability: The durable construction of the panel ensures its reusability over multiple construction projects, promoting sustainability and cost-effectiveness.

The Beam Side Panel is a vital component in aluminum formwork systems as it provides essential support and stability to the sides of beams during the concrete pouring process. Its precision, ease of use, and durability contribute to efficient and high-quality construction processes, resulting in well-formed and structurally sound beams.